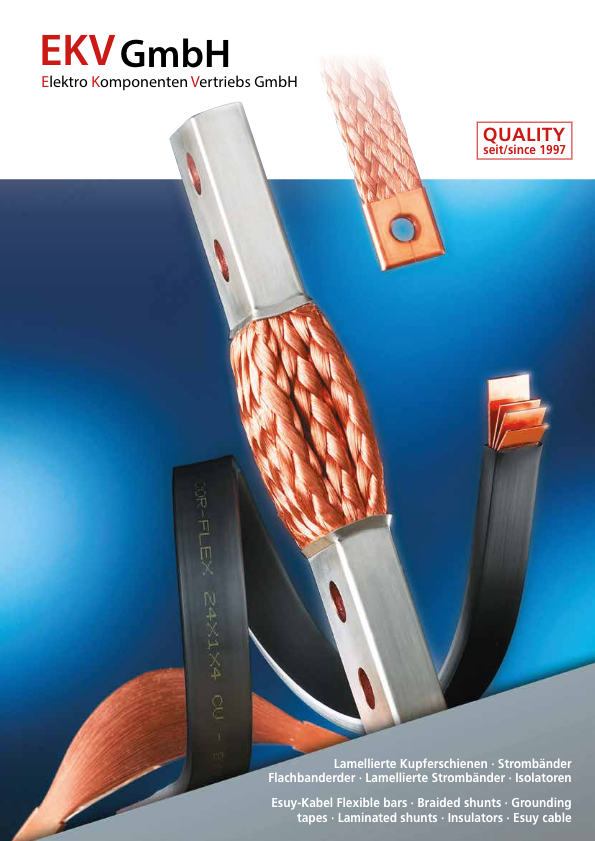

Flexible Expansion connectors

This flexible copper connectors will be used as a power transmitter which allow movements. Typical operational areas are at welding nippers, transition from transformers to bus bar systems to absorb vibrations and switch actions.

Contact areas of the flexible expansions connectors could be produced in two different ways:

Press welded

These connectors are constructed from Cu-HCP foils with a thickness of 0,10 to 0,30mm by overlapping the needed amount together and welding their ends a required contact area without using any welding additive. This special welding process takes places under high pressure and intensive heat. These connectors have a uniform cross-section over their entire length and due to their homogeneous molecular structure; they are perfect electrical conductors.

As press-welded expansion connectors can be subjected to the same loads as the corresponding bare busbars.

Press riveted

The C Cu / Cu ETP strips with 0,10 or 0,20mm thickness are connected with pressing and riveting them together fort he needed shape. Contact areas are additionally strengthened with thicker copper sheets. These kind of connectors are mainly used where you need two dimensional movements, greater current transfer and resistance against heat such as welding guns and machines. By this kind of connection you could use tin plated foils too.

We could produce this flexible expansion connectors in different width, length, bending’s (S-, U- and V-shape). Holes could be drilled according your wishes. Thickness of the single layers from 0,10mm up to 0,30mm. You see in the catalogue solution which we could produce but over 90% of our production is customized material according your drawing. We could produce items with sizes from matchbox up to euro pallet.

Current flow depends on the cross section and the size and surface of the contact area. We could calculate this values for your if needed.