Braided shunts / connections without insulation

The contact area of this braided shunts will be pressed with high pressure into solderless seamless Cu Tube. The braided tapes and the tubes are of same the analysis and conductivity. No additives are used for the process of pressing the contact areas. During this process the braid and the tube will be extremely ramming squeezed and provide very junction values. This packing protects the item for environmental impact too.

We could produce the terminal in different shapes for the same cross section. Extreme flat and more width or very compact because of this production method. Also, the length of the terminal is customizable.

The braid is available in different diameter of the single wire. We offer you the following solutions: Ø 0,07 / 0,10 / 0,15 / 0,20mm. Beside the different sizes of the single wire we provide a multitude of cross sections starting from 2,5² up to 4500².

The design of a typical flexible copper connector is round or flat, with a contact area and drilling at both ends. We can also produce variations of this. Examples for this could be multilayer over or beside each other. Contact areas with 90° turned position, different sizes of the contact area or hole pattern.

Some instance of this you can see in the sketches below.

Different hole pattern diameter of the holes and positions are possible.

We provide red copper, tinned copper, aluminum and stainless steel for the braid and the tubes.

We produce the items which you find in our catalogue, variations of this, (different length, width, dimension of the contact area) and complete customized braided shunts according to your drawing.

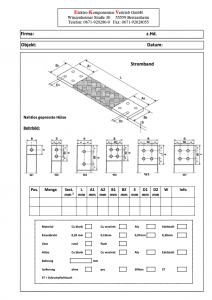

If you don’t have a drawing, you can use our request form. Please fill in the values you have and send us the blank. We will check this and send you an offer.

You can find an overview here: